Coatings

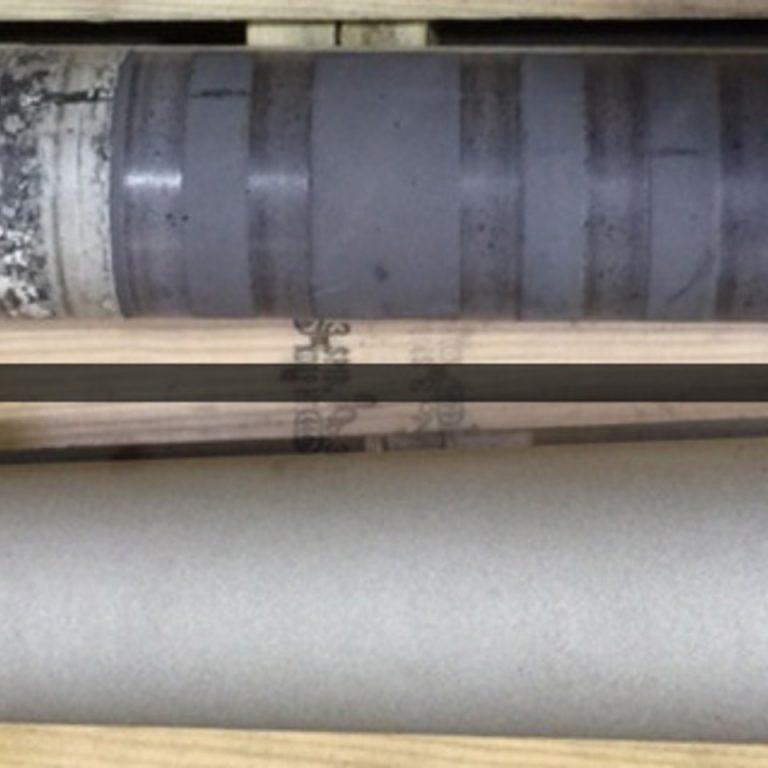

The majority of our Coatings work is for Rollers

of every size, shape & application.

Whether you are in the Printing, Packaging or Converting Equipment Industry, having the proper coating on your rollers and other equipment parts is vital for sustaining your operation. We offer all types of coatings to help you protect your machinery and to extend the life of expensive and vital components.

We also work in the Flexible Packaging Food Service, labels, film, ink, paper, plastics, rubber, metals, specialty metals, steel and wind energy industry segments. Chrome roller repairs are extremely popular at MGF.

Common Projects Include:

- Shafts

- Idler Rollers

- Spreader Rollers

- Squeeze Rollers

- Wrinkle Eliminating Rollers

- Anilox Rollers

- Ink Fountain Rollers

- Water Transfer Rollers

- Knurled Rollers

- Ink Vibrators Rollers

- Draw Rollers

- Jaw Blades

For Flexo Packaging/Converting:

- Accumulator Rollers

- Actuator Shafts

- Adhesive Pans

- Air Shafts

- Back Up Rollers

- Pull Rollers

- Calendar Rollers

Solutions

Printing : Rolls, Former Boards and Knives

Packaging & Converting: Cylinders with Mirror Finish

- Hard Chrome Plating

This typically applies to parts with heavy wear, that need their dimension(s) brought back to OEM specifications. Chrome build-up is very beneficial on parts that are exposed to the toughest of conditions, due to chrome’s durability. - Superfinishing Cylindrical

Also known as micro finishing, this metal working process improves surface finish and work piece geometry and produces a mirror finish. MGF’s polish and superfinishing capabilities and equipment enables us to achieve finishes to 0.25 micro inches on the Ra scale. We have experience in the following applications: plastic laminating rollers, sheet die, water metering rolls, feed rolls, calendar rolls, cooling drums. - Flash Chrome

This is a very thin layer of chrome consisting of deposits with a thickness of 0.00005” to 0.0001”. It’s ideal for applications needing a light wear and corrosion protections, reduced coefficient of frictions, improved release properties, along with tight tolerances where post plating processes are not practical. Specifically: inserts, cavity blocks, core pins, injection mold components, extrusion molds, crimpers, rollers. - Chrome Croydon

This finish is achieved by sandblasting the area to a specific RA. We then chrome plate the part to required thickness. Many of these parts are used for gripping purposes with enhanced wear and when corrosion resistance is needed.

We offer a variety of coatings to salvage worn parts, mis-machined and new components. This restores the life of critical parts, and surfaces are enhanced to improve performance. Industries served include: printing, packaging, food, pharmaceutical and mechanical engineering.

We offer a variety of coatings to salvage worn parts, mis-machined and new components. This restores the life of critical parts, and surfaces are enhanced to improve performance. Industries served include: printing, packaging, food, pharmaceutical and mechanical engineering.

Capacity for Coatings:

Outside Diameter: 72″ x 240″

Internal Diameter: 5″ x 40″

Traction Coating

Applications: winder drum, reel drums, re-reelers, felt rolls, segmented slitter guides, sheeter draw rolls

Corrosion Resistant Coating (Corrosion/Mirror Finish)

- Tungsten Carbide/cobalt/chrome Coating-HVOF

- Applications: Suction Press and Sym Rolls in paper mills. Ideal for super-calendaring, cast film extrusion.

High Release Coating

Applications: Idler Rolls and components used in adhesives, hot plastics and other tack material.

Metallic Coating (Sealed Aluminum coating)

- Aluminum/epoxy coating provides dual protection against corrosion.

- Applications: Fly Rolls, in the Supercalendar section.

- Coating thickness: .006/.010

- Max. service Temp: 250 degrees

- Surface Finish: 100-200 Ra

Ceramic Coating

Ceramic characteristics make them a superior choice over carbon hardened or stainless steel, copper and chrome processes, which are subject to high-surface wear. Ceramic dampening rollers provide outstanding performance and require less maintenance than chrome rolls because of their unique ability to resist abrasion and corrosion while maintaining a consistent surface finish across and around the entire roll. Ceramic can be impregnated with other materials such as Teflon ® for use as easy-cleaning or traction-control idlers, depending on the surface specified (smooth or rough).

Electroless plating involves the production of coatings from solutions of metal ions without the use of an external source of electrical energy. It is the most extensively used electroless coating within the manufacturing industry and the most prevalent for engineering purposes.

Electroless plating involves the production of coatings from solutions of metal ions without the use of an external source of electrical energy. It is the most extensively used electroless coating within the manufacturing industry and the most prevalent for engineering purposes.

Advantages of Electroless Nickel Plating

- Excellent corrosion resistance

- Excellent wear and abrasion resistance

- Good ductility, lubricity and electrical properties

- High hardness, especially when heat-treated

- Good solderability

- Even and uniform thickness even down deep bores and recesses, and at corners and edges

- The coating can be applied as the final production operation and can meet stringent dimensional tolerances

- Can be used on both metallic and non-metallic substrates, provided they have been suitably pre-treated

Industries that Extensively Use Electroless Nickel Plating

- Automotive: Cylinders, gears, shock absorbers, brake pistons, heat sinks, etc.

- Aviation and Aerospace: Components for rockets and satellites, valves, rams pistons, etc.

- Chemical Processing: Mixing blades, filter units, heat exchangers, pump housings, impellers, etc.

- Petroleum and Gas: Plugs, gates, balls and other valve components, pipe fittings, barrels, pumps, packers, etc.

- Plastic Manufacturing: Injection molds and dies, low and blow molding for plastics components, rollers, extruders, etc.

- Textiles: Machine parts, threaded guides, spinnerets, printing cylinders, etc.

- Food and Pharmaceuticals: Food molds, food processing machinery components, capsule machinery dies, etc.

MGF Services provides a turn-key product: Newly produced grinding, grooved patterns with precision and custom made to your specifications.

MGF Services provides a turn-key product: Newly produced grinding, grooved patterns with precision and custom made to your specifications.

- Flexible packaging

- Printing

- Newspaper

- Textiles

- Corrugated

- Metal Decorating

We also work with the food processing, film, ink, paper, plastic, rubber, metals, specialty metals, steel and wind energy industries.

Proper coatings protect your machinery and extend the life of expensive parts, making it a very smart investment for any shop.

These coatings include:

Proper coatings protect your machinery and extend the life of expensive parts, making it a very smart investment for any shop.

These coatings include:- Carbide

- Ceramic

- Corrosion Resistant

- High Release

- Fluoropolymer

- Metallic

- Traction

Printing : Rollers Textiles.

Pharmaceuticals & Food: Rollers.

Printing : Rollers Textiles.

Pharmaceuticals & Food: Rollers.

Quality printing is highly dependent on the proper distribution and transfer of the printing ink. The quality of the coating on the inker vibrator rollers is a particularly key factor and should not be underestimated. Like many of the OEM printing press manufacturers, we recommend Rilsan because it has excellent resistance properties to the chemical effects of the printing inks. The absorption of water and ink is very low and the surface is smooth and durable.

In many cases, Rilsan would replace Copper or Ebonite in ink vibrator roller positions, and a knurled Rilsan ink metering roller would replace Steel or Copper in continuous inkers where medium to heavy ink coverage is required. For light ink coverage applications such as black type book work, Copper remains the preferred covering in continuous inkers due to its low ink and high heat transfer coefficients.

Rilsan offers the Roller Industry:

- Exceptional resistance to wear for longer service life

- Hardness designed for uniform pressure

- Smooth surface finish and low friction which leads to easy cleaning

- High resistance to inks and solvents

- Machining suitability and dimensional stability

- Cores are electro-cleaned and rinsed

- Preheating and prime bonding agent seal core

- Machine-finished ends provide material overlap on radius

- Journals polished and coated

- Wrap finished surfaces with poly-liner paper

- Protective wrap with corrugated paper

Get Started