Understanding Harden Slitters, Anvil, and Score Rollers for Printing, Packaging, and Industrial Industries

I get lots of questions about Harden Slitters, Anvil, and Score Rollers from my clients and potential clients in the Printing, Packaging, and Industrial industries. There are hundreds of designs fo...

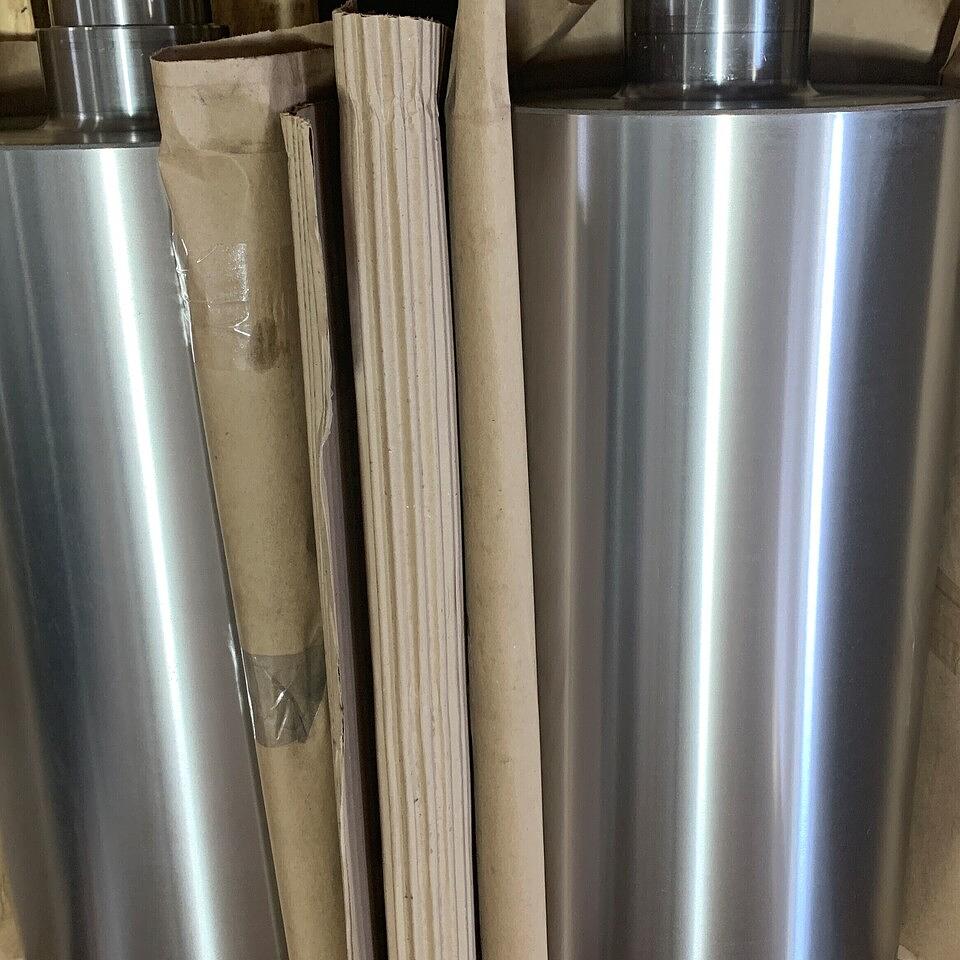

Nylon Rollers

I’ve worked around “Rollers” for decades. I practically grew up around them. Rollers are such an important component of any press and lots of industrial manufacturing machinery. Rollers get used a lot in a variety of ways. Whether they’re pushing something through or slowing something down, there is a constant state of friction. Friction causes wear. And rollers can wear out quickly. But now, t...

Basics of Draw Rollers in Paper Machinery

Draw rollers, also known as pull, traction, driven, all have one thing in common: Tungsten carbide (Wolfram) coating.The primary function of draw rollers are to guide and draw paper. The coatings on the roller determine the “lifespan of the roller.” The life of the roller coating depends on the operational use, of course. Typically, however, this coating will last years. How do you know when it...

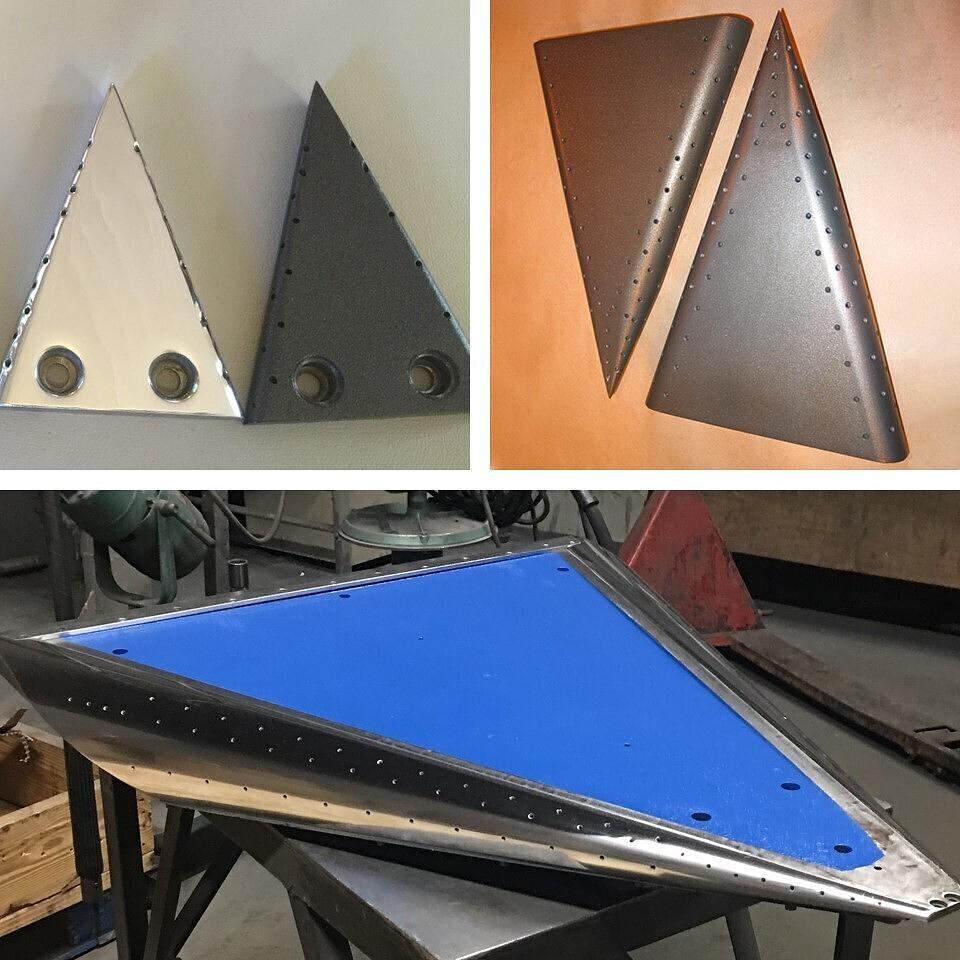

Should you repair or replace your Printing Machinery Parts?

The printing industry is ever-changing, but your machines are always running. When things start to fail, how are you supposed to know if it’s better to repair or replace your machinery parts? Unless a part has reached its threshold to repair, you should be able to refurbish most mechanical applications. Such as:Ceramic rollersIdler rollers used in handling adhesives, hot plastics, sticky materi...

Things to Consider with Surface Coatings

In today’s technology, thermal coatings have become Surface Engineered Solutions, which can be overwhelming to companies looking for repair or new applications. Things to consider:Materials-substrate/coating/sealerTemperature-Processing/operatingShape of part-line of sightSize of part to be coatedCoating thicknessOperating environment What are you trying to accomplish?Wear resistanceCorrosion/c...