HIGH SPEED TOPSIDE UV COATER

Overview

The Scheffer International (SI) High Speed Topside UV Coater is a cutting-edge machine designed to meet the needs of modern web printing operations. Engineered for applying a diverse range of UV-cured coatings—including dull, high-gloss, and textured finishes—this coater is ideal for products such as covers and inserts. With its high-speed performance and versatility, the SI UV Coater provides spot or full UV coverage across the entire web width, ensuring optimal results in demanding printing and finishing environments.

Key Features

Independent Servo Drive:

Equipped with a dedicated servo motor, software, and controls supplied by SI for precise and reliable operation.

Drive & Electrical Package:

Motors and drives for both the UV coater and chill rolls

Press stations located at entry and exit sides for seamless integration

Remote diagnostic system accessible via Ethernet for efficient troubleshooting and support

Stainless Steel Magnetic Plate Cylinder:

Features a 0.067” (1.702mm) undercut for optimal coating application.

Nickel Plated Impression Cylinder:

Provides durability and consistent performance.

Laser Etched Ceramic Anilox Transfer Cylinder:

Ensures precise coating transfer and long-lasting reliability.

Pneumatically Engaged, Self-Adjusting Doctor Blade:

Offers automatic adjustment for consistent coating quality.

Hi-Lo Level Sensor UV Pan:

Monitors and maintains optimal coating levels in the pan.

UV Coating Circulation Pump:

Ensures continuous and even distribution of UV coatings.

Chill Rolls:

Two chill rolls with variable speed drive for effective web cooling and process control.

Adjustable Nip Roller:

On-the-run adjustment with (+/-) speed readout for precise pressure control.

Ultraviolet Curing System

Ultraviolet Curing System

Lamp Housings:

Four single lamp housings, each with a 1000 watt per inch lamp for powerful and efficient curing.

PLC Controls:

Programmable Logic Controller enables flexible and automated operation.

Operator Interface:

Touch screen controller offers intuitive and user-friendly management of all system parameters.

Available Options

Automatic lubrication system for reduced maintenance and improved longevity

Ladder, platform, and hand-rails for enhanced operator safety and access

Web break detector for increased process reliability

Web severer for emergency or controlled web cutting

Applications

The SI High Speed Topside UV Coater is perfect for printers and converters who demand high-quality UV coatings on a variety of substrates. Its inline design enables seamless integration with web presses, making it well-suited for continuous production environments where efficiency, quality, and flexibility are essential.

Summary

By combining robust construction, advanced automation, and flexible configuration options, the SI High Speed Topside UV Coater stands out as a premier solution for demanding UV coating applications in the printing industry. Whether you need spot or full coverage, this coater delivers consistent results with minimal downtime and maximum productivity.

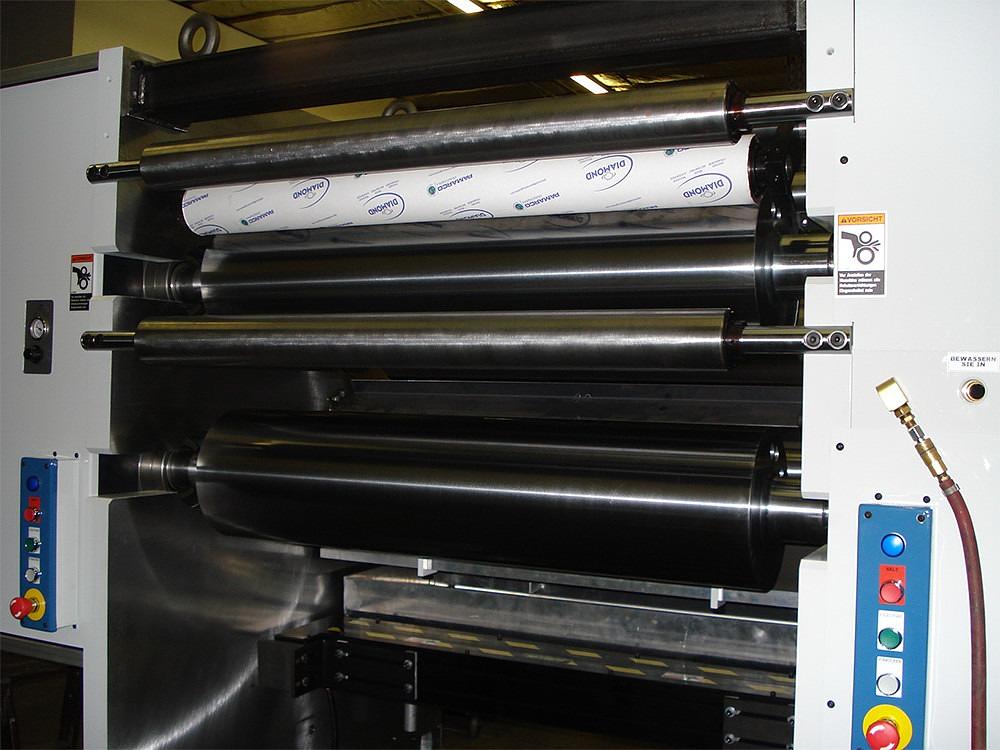

Below are some sample photos showcasing various UV Coater applications:

UV Lamps Curing System UV Coater, Anilox Transfer Cylinder UV Coater, and Chill Roll Assembly UV Coater.